- Joined

- Dec 7, 2003

- Thread Starter

- #61

Thanks!

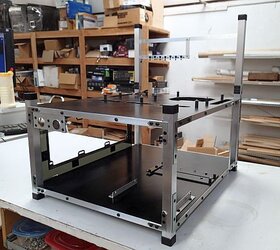

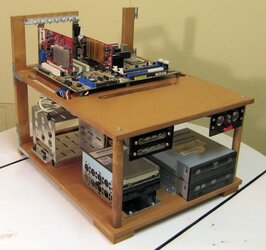

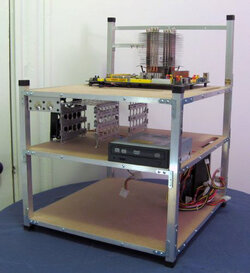

Final Assembly

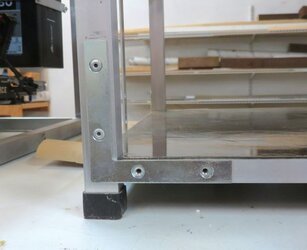

First I attached my 4 posts to the bottom panel.

Each L bracket attaches to panel with 2 screws. So I fit the post to the panel side,making sure everything is nice and square, and mark my holes with a pencil onto the surface of the aluminum trim piece underneath. Then I center punch the holes, drill them with my #36 drill bit, threw the aluminum trim and then down into the MDF panel underneath, to about the depth of ¾”. Then I tap out the holes.

Each post has 8 mounting points to the panels, so this process get repeated 32 times!

Got the bottom panel attached:

Attached the top panel.

Mounted the PCI bracket.

Mounted the power supply bracket:

Mounted the radiator bracket:

And any other brackets such as the Brollocks fan bracket:

Somewhere along the way, also added black plastic end caps:

McMaster Carr web link:

https://www.mcmaster.com/#92675k43/=19txbqw

When I’m adding the plastic caps, I know I’m pretty much finished!

Final Assembly

First I attached my 4 posts to the bottom panel.

Each L bracket attaches to panel with 2 screws. So I fit the post to the panel side,making sure everything is nice and square, and mark my holes with a pencil onto the surface of the aluminum trim piece underneath. Then I center punch the holes, drill them with my #36 drill bit, threw the aluminum trim and then down into the MDF panel underneath, to about the depth of ¾”. Then I tap out the holes.

Each post has 8 mounting points to the panels, so this process get repeated 32 times!

Got the bottom panel attached:

Attached the top panel.

Mounted the PCI bracket.

Mounted the power supply bracket:

Mounted the radiator bracket:

And any other brackets such as the Brollocks fan bracket:

Somewhere along the way, also added black plastic end caps:

McMaster Carr web link:

https://www.mcmaster.com/#92675k43/=19txbqw

When I’m adding the plastic caps, I know I’m pretty much finished!